SPECIFIC PROCESSES

HIGH QUALITY EQUIPMENT

Melting

2 dry hearth furnaces with a capacity of 500 and 1000 kg / hour

2 crucible furnaces with a capacity of 300 kg / hour

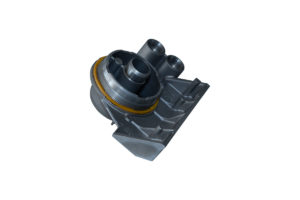

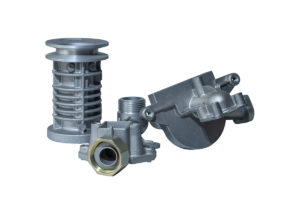

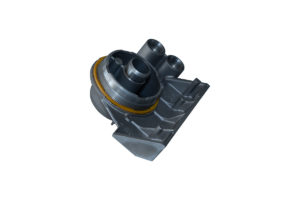

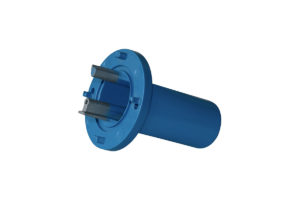

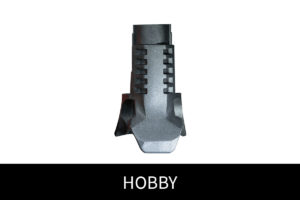

Die casting

2 semi-automatic high pressure die casting machines

10 robotic high pressure die casting cells from 340 t to 900 t

Die trimming

15 trimming presses ranging from 15 to 65 tons

Mechanical deburring

1 drum shot blast machine

1 spinner hanger shot blast machine

2 vibrators: 1 tub and 1 rotary

2 ball burnishing machines with stainless steel media

Machining

3 CNC controlled lathes

2 machining cells

15 CNC controlled machining centers

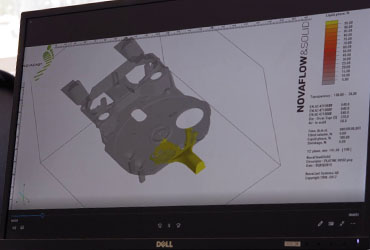

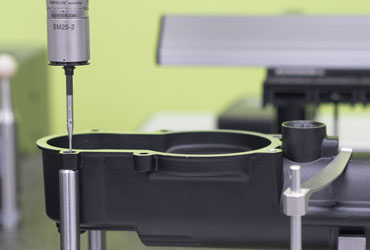

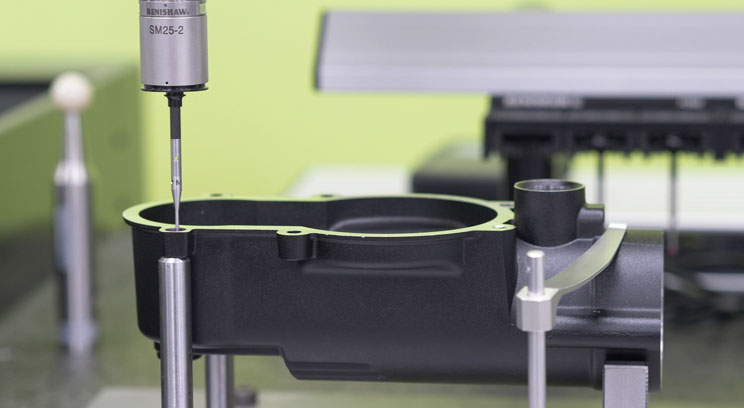

Inspection

Spectrometer

3D measuring machines

1 optical comparator

1 cleanliness test lab (particulate contamination)

1 tomography and X-Ray machine

OUR BUSINESS SECTORS

QUALITY STANDARDS

Committed to a process of continuous improvement, Fonderie de la Bruche has naturally turned towards recognised quality standards. Customer satisfaction, performance improvement, staff motivation, development and promotion of high-pressure die-casting jobs are the guidelines of Fonderie de la Bruche’s quality policy.